P&ID vs. Schematic

If you’re working in engineering or just getting into it, you’ve probably come across the terms P&ID and Schematic. These diagrams are essential tools that help professionals design, build, and understand complex systems. But what exactly are they, and how are they different? Let’s break it down in simple terms with easy-to-understand examples.

What is a P&ID?

P&ID stands for Piping and Instrumentation Diagram. Think of it as a detailed map of a factory or a plant. It shows how the pipes, machines, and control devices are connected and interact with each other.

Example: Imagine a big factory that makes soft drinks. A P&ID for this factory would show the pipes carrying the liquids, the tanks where the drinks are mixed, the pumps that move the liquids, and the sensors that measure things like temperature and pressure. It’s like a blueprint that shows how everything is connected and works together.

What is a Schematic?

A Schematic is more like a simplified diagram that shows how a system works, but without focusing on the exact locations of each part. It’s more about showing the flow of electricity or signals rather than the physical layout.

Example: If you think about a simple flashlight, a schematic would show the battery, switch, and bulb, and how electricity flows from the battery, through the switch, to light up the bulb. It doesn’t show where these parts are physically located, just how they are connected.

Key Differences Between P&ID and Schematic

- Purpose:

- P&ID: Used to design and operate process plants, showing all the pipes, equipment, and controls.

- Schematic: Used to understand and design electrical circuits or other systems, focusing on how things are connected.

- Level of Detail:

- P&ID: Very detailed, showing exact connections and equipment.

- Schematic: More abstract, showing how things work together without worrying about their physical location.

- Example to Compare:

- In a P&ID for a soft drink factory, you’d see how the sugar syrup flows through pipes to mix with water and flavoring in tanks, with sensors monitoring the process.

In a Schematic for a flashlight, you’d see how the switch controls the flow of electricity from the battery to the bulb, making it light up when you turn it on.

Why Understanding Both is Important

Even if you’re just starting in engineering, understanding the difference between P&ID and Schematic diagrams is important. They each serve different purposes but are both crucial for making sure everything works as it should. Knowing how to read and use these diagrams will help you design, build, and troubleshoot systems more effectively.

To sum it up, a P&ID is like a detailed map showing how every pipe and machine in a factory is connected, while a Schematic is a simplified diagram showing how electricity or signals flow through a system. Both are essential tools in engineering, but they are used for different purposes. By understanding the difference, you’ll be better equipped to work on a variety of projects.

FAQs

What does P&ID stand for?

P&ID stands for Piping and Instrumentation Diagram. It’s a detailed diagram that shows how pipes, equipment, and control devices are connected in a process plant.

What is the main purpose of a P&ID?

The main purpose of a P&ID is to provide a clear and detailed overview of the piping, equipment, and control systems in a plant. It helps engineers design, operate, and maintain the plant efficiently.

What does a Schematic diagram show?

A Schematic diagram shows the functional relationships and flow of electricity or signals within a system. It focuses on how components are connected rather than their physical location.

How is a P&ID different from a Schematic?

A P&ID is more detailed and shows the exact physical connections and locations of components in a process plant. A Schematic, on the other hand, is more abstract, showing how components are connected in terms of function, without worrying about physical layout.

In what industries are P&IDs commonly used?

P&IDs are commonly used in industries like chemical processing, oil and gas, pharmaceuticals, and manufacturing, where complex process systems are involved.

Can a Schematic be used to design electrical systems?

Yes, Schematics are often used to design electrical systems, as they show how components like resistors, capacitors, and switches are connected to create a working circuit.

Why is it important to understand both P&ID and Schematic diagrams?

Understanding both P&ID and Schematic diagrams is important because they serve different purposes in engineering. P&IDs help in the physical design and operation of process plants, while Schematics are crucial for designing and troubleshooting electrical and mechanical systems.

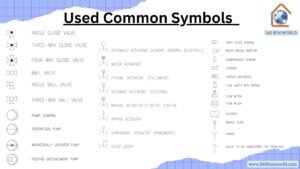

What symbols are used in P&ID diagrams?

P&ID diagrams use standardized symbols to represent different components, such as pumps, valves, sensors, and control systems. These symbols ensure consistency and clarity in the design process.

Are Schematics used only in electrical engineering?

While Schematics are most commonly associated with electrical engineering, they are also used in other fields like electronics and mechanical engineering to represent systems and circuits.

How can I learn to read P&ID and Schematic diagrams?

To learn to read P&ID and Schematic diagrams, you can start by studying the symbols and conventions used in each type. Practice with real-world examples and consider taking courses or tutorials that focus on these diagrams in your specific industry.